Project description

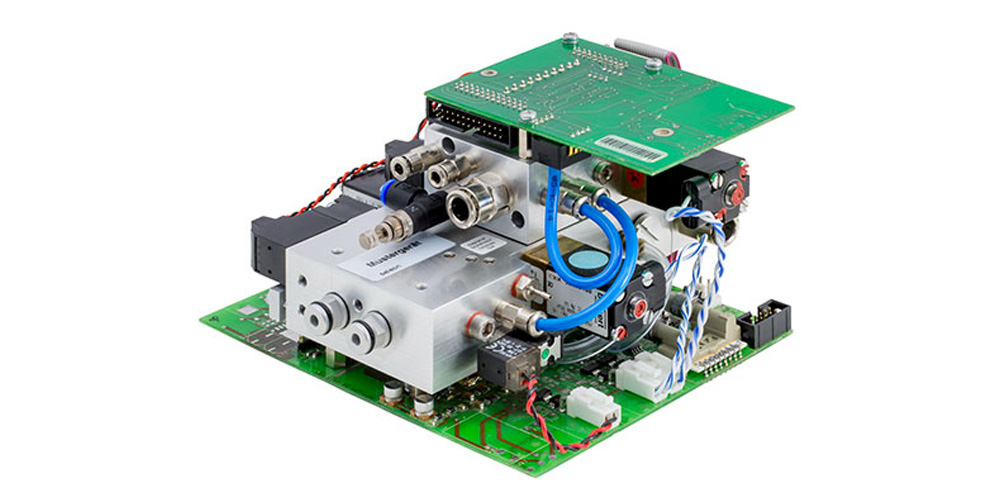

The digital gas mixer is used to produce predetermined oxygen concentrations (from compressed air and oxygen) or gas mixtures of a maximum of four gases. It is integrated as a modular assembly into various ventilators in paediatrics and anaesthesia machines.

The gas mixer is suitable for versatile use in various ventilators and anaesthesia machines with different requirements and measuring ranges. The oxygen concentrations as well as the pressure and volume flow are adjustable.

Project task

The entire development and production process for the device was carried out in-house at seleon and is manufactured in accordance with the DIN EN ISO 13485 standard. The customer received the product developed according to his ideas and is the owner of the patent. Development and production were realised in a cost-conscious manner. Repairs and servicing of the device are carried out on behalf of the customer.

seleon GmbH was responsible for the development, design and manufacture through to series production of the gas mixer. The aim was to increase the accuracy and safety of the gas mixer. In addition, costs were to be reduced by digitalising the mixing process. When integrated into ventilators, the gas mixer also has to provide a specified pressure or volume flow. It must meet the special requirements for safety and alarm functions in the paediatric sector.

Installation in various devices required a compact and small design, and the number of outputs varies. Installation should be simple and firmware updates must be possible at a later date.

seleon’s extensive expertise and experience in the field of ventilator technology led to intelligent solutions during the development process, which resulted in a patent.

Do you have any questions?

Our colleagues will be happy to answer any questions you may have.

LINUS YMAN

SALES MANAGER

linus.yman@seleon.com

+49 174 748 10 52

BENJAMIN KLEIN

SALES DIRECTOR

benjamin.klein@seleon.com

+49 152 5781 0356