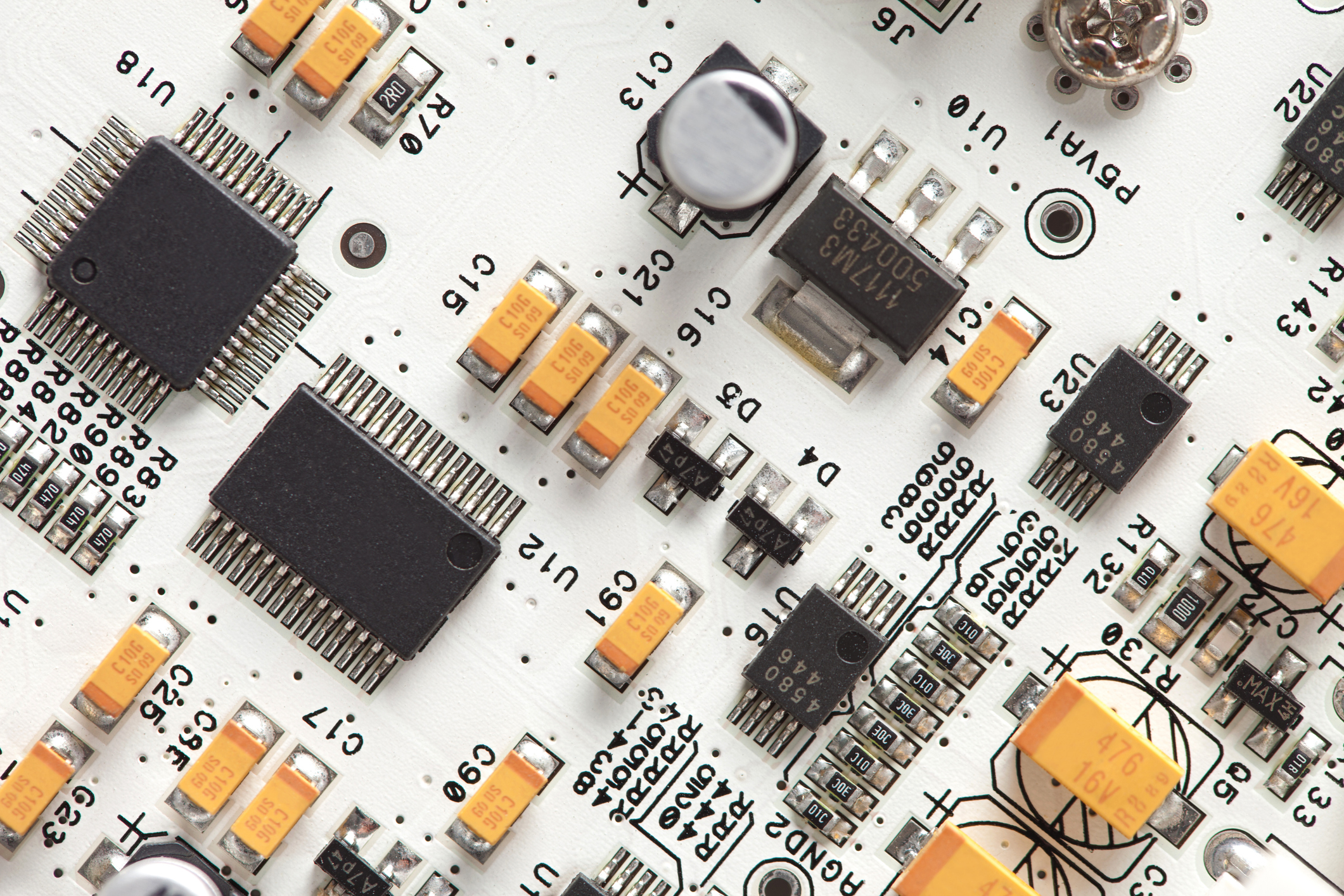

In our latest blog post, we provide insights into our proven strategy for dealing with discontinued devices and components for medical systems and solutions. Learn more about our approach and the challenges involved.

The initial situation: Dealing with discontinued devices and components in medical technology

In recent years, the availability of materials has changed drastically worldwide. We used to be able to access materials almost overnight if there were shortages in the warehouse. Nowadays, however, we are confronted with material cancellations almost daily or have to put up with extremely long delivery times. In the high-tech medical technology market in particular, this is a serious problem that can lead to production delays or, in the worst case, even to production being halted.

Experienced development teams and innovative methods to overcome material availability problems

The collaboration of an experienced development team with an experienced purchasing team and the use of suitable tools means that extreme situations can be recognised and avoided at an early stage. It also enables countermeasures to be taken in good time. This includes early research into alternative components and assemblies to replace discontinued parts in medical devices. As soon as new reports on the component situation are received that require an immediate response, each report is evaluated by our experienced development team to determine whether action is required or whether the report can be mitigated and processed without a potential change.

Continuous monitoring is the keyword

By continuously monitoring all components during the development phase of medical devices, potential candidates for discontinuation or long delivery times can be identified at an early stage. In this way, measures can be taken in good time by introducing alternative components without the need for a formal change process. This makes it possible to avoid bottlenecks and long delivery times at the start of series production, including the pilot series and the first series production.

Monitoring of series productionn

Even after the start of series production, continuous monitoring remains the means of choice to keep up to date and to be informed about discontinued components. This enables an early start to possible changes should they occur. In combination with optimally placed last time buy activities, sufficient time can be gained to implement changes, depending on their scope, in such a way that there are no delays in series production.

Using the right tools is the key to success

By using the right tools and configuring them, notifications of status updates for individual components are automatically sent to the responsible colleagues by e-mail. In addition to the name of the component, the changed status and a link to the data sheet, alternatives are also suggested to replace the discontinued component. In addition to the configuration of the tool, the prerequisite for these automatic notifications is the uploading of complete parts lists of the components or assemblies that are to be monitored. Certain criteria for the appearance of the parts list must be followed and nothing stands in the way of continuous monitoring.

Conclusion

Continuous monitoring of components is essential if surprises at the end of development or during series production are to be avoided. This avoids the consequential costs of production delays or even downtime.

seleon has already integrated the continuous monitoring of components into the process during development and also offers this service to any customer who expressly requests it. This also includes all customers who have their medical devices manufactured by seleon.

If you would like to learn more about our proven approach to dealing with material availability issues, please do not hesitate to contact our sales team directly. We will be happy to answer your questions and support you in successfully realising your projects.

Please note that all details and lists do not claim to be complete, are without guarantee and are purely for information purposes.